Solution

Industrial equipment failure prediction solution

Predictive Maintenance

AI-powered Predictive Maintenance Platform

Industrial Equipment Failure Prediction Solution

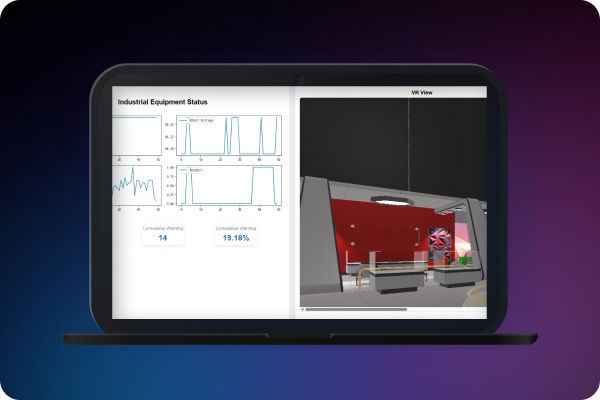

MyMeta’s predictive maintenance solution combines IoT sensor data with AI algorithms to detect abnormal signs in real time and predict equipment failures in advance. This enables companies to minimize production downtime, reduce maintenance costs, and prevent safety incidents.

01

Real-Time Anomaly DetectionAnalyzes sensor data every second to instantly detect abnormal patterns before failures occur.

02

Failure Prediction ModelsApplies high-reliability AI algorithms such as LSTM, AutoEncoder, and XGBoost.

03

Explainable AI GuidanceAutomatically provides root cause analysis and recommended countermeasures using LLM.

04

Visualization DashboardWeb-based admin UI to monitor equipment status, alerts, and maintenance history.

Provides not just alerts, but also “failure cause interpretation + response guidance.”

Integrated with Oracle AI Cloud to ensure global SaaS scalability and security.

Successfully validated through PoC in real manufacturing lines such as KB Autosys.

Applicable across industries including semiconductors, secondary batteries, automotive, components, and chemical plants.

Improved Equipment Uptime

(Minimized Downtime)

Reduced Maintenance Costs

(Fewer Unnecessary Inspections)

Enhanced Safety

(Proactive Prevention)

Accelerated Smart Factory Adoption

and Global SaaS Expansion

Join MyMeta in shaping the future of AI solutions

Want to know more about MyMeta’s solutions?수영장 이용시간은 어떻게 되나요?

질문 다시보기

-

1. Purpose of Collecting and Using Personal Information

Identification of applicants, verification of identity, recruitment process (confirmation of acceptance), and handling inquiries.

-

2. Collected Personal Information Items

[Required]: Name, Email address, Phone number

[Optional]: Job posting, Resume, Referee -

3. Retention and Use Period

Recruitment information: 2 years from application submission, registration in the talent pool for ongoing recruitment.

Applicant information will be stored in the company’s talent pool for 2 years for future recruitment needs.

Applicants may request deletion of their information at any time via daniel@e-mymeta.com.

As per the Fair Hiring Procedure Act, paper-based applications will be kept between 14 to 180 days from the end of the recruitment process.

Applicants may request their return within this period. Requests can be made via daniel@e-mymeta.com and documents will be returned within 14 days, postage paid by the applicant. After this period, or if not requested, documents will be destroyed in accordance with the Personal Information Protection Act. -

4. Right to Refuse Consent and Possible Disadvantages

Applicants may refuse to consent to the collection and use of personal information.

However, refusal to provide required information may restrict participation in the recruitment process.

Submitted data will be retained for 2 years. If deletion is requested, please contact daniel@e-mymeta.com, and it will be promptly removed.

-

1. Purpose of Collection and Use

Preference for persons with disabilities under the Employment Promotion and Vocational Rehabilitation Act for Persons with Disabilities [Act No.14839].

-

2. Sensitive Information Collected

Disability status (type of disability).

-

3. Retention and Use Period

Recruitment information: 2 years from application submission, registration in the talent pool for ongoing recruitment.

Applicant information will be stored in the company’s talent pool for 2 years for future recruitment needs.

Applicants may request deletion of their information at any time, which will be promptly processed. -

4. Right to Refuse Consent and Possible Disadvantages

Applicants may refuse to consent to the collection and use of sensitive information.

However, refusal to provide required information may restrict participation in the recruitment process.

Submitted data will be retained for 2 years. If deletion is requested, please contact daniel@e-mymeta.com, and it will be promptly removed.